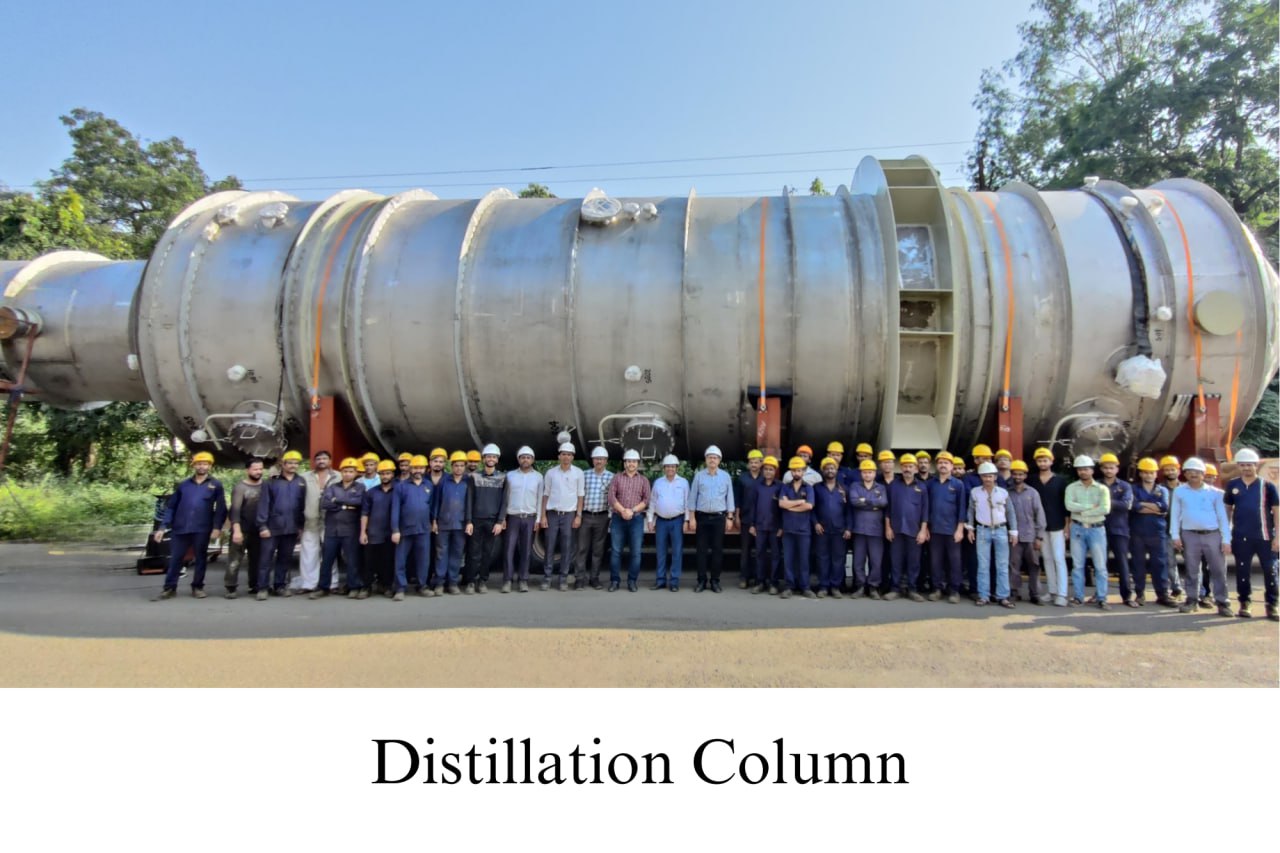

R&D Therm is a leading global manufacturer of distillation columns, designed to deliver high-efficiency separation of liquid mixtures into their component parts or fractions based on differences in volatilities. Certified with the ASME U stamp, our distillation columns are built to meet the rigorous demands of industries such as petroleum refining, alcohol distillation, and pharmaceutical production.

A distillation column is a critical piece of equipment used in the distillation process to separate liquid mixtures into their individual components. By leveraging differences in the volatilities of the mixture’s constituents, distillation columns enable precise fractionation, making them indispensable in various industrial applications.

R&D Therm offers a range of distillation column designs to cater to diverse operational needs:

Batch Columns: Ideal for batch-wise separation, offering flexibility for smaller-scale or specialized processes.

Continuous Columns: Designed for large-scale, uninterrupted operations, ensuring high throughput and efficiency.

Packed Columns: Utilize packing materials to enhance separation efficiency, perfect for applications requiring high precision.

Our distillation columns are engineered to support a wide range of industries, including:

Chemical Processing : For separating and purifying chemical mixtures in bulk chemical manufacturing, fine chemicals, and specialty chemicals.

Food and Beverage Industry: Used in the purification of essential oils, flavor extraction, and alcohol production processes like vodka, whiskey, and rum.

Biofuels Production:Separating bio-based feedstocks into fuel-grade components, such as ethanol, biodiesel, and other renewable fuels.

Solvent Recovery Systems: Recovering and recycling valuable solvents from industrial processes, reducing waste and improving sustainability.

Environmental & Waste Treatment: Used in processes like solvent stripping, VOC recovery, and waste minimization in effluent streams.

Essential Oils & Fragrances: Fractionating and purifying natural oils for perfumes, cosmetics, and aromatherapy applications.

Agrochemical Industry: Separating and purifying intermediates and final products in the production of fertilizers and pesticides.

Pulp & Paper Industry: Recovering and purifying by-products like tall oil, turpentine, and other volatile organic compounds (VOCs).

LNG & Gas Processing: For separation of hydrocarbons in cryogenic processes, such as separating methane, ethane, propane, and butane.

Plastic & Polymer Industry: Purifying monomers and solvents for polymerization processes, ensuring high-purity raw materials for plastics production.

Pharmaceutical Intermediates: Separating and purifying intermediates in multi-step pharmaceutical syntheses, ensuring product consistency and purity.

Perfume & Aroma Chemical Manufacturing: For the distillation of aromatic compounds, ensuring consistency and purity in fragrance production.

Dye and Pigment Manufacturing: Purifying organic solvents and intermediates for the production of high-quality dyes and pigments.

High Efficiency: Optimized designs for maximum separation accuracy and throughput.

Robust Construction: Built to withstand demanding industrial environments.

Customizable Solutions: Tailored to meet specific process requirements.

Compliance with Standards: Manufactured in accordance with ASME Section VIII for safety and reliability.

Stainless Steel / Carbon Steel / High Alloy Steels like Titanium, Hastelloy, Sanicro 28.

All R&D Therm distillation columns are manufactured in strict compliance with ASME Section VIII, guaranteeing the highest standards of quality and safety. Our certified welders employ cutting-edge techniques to deliver products that are built to last.

1. What makes R&D Therm's distillation columns highly efficient for industrial separation?

R&D Therm designs distillation columns with advanced engineering and precision manufacturing to ensure maximum separation efficiency, higher purity, and reduced operational costs across various industries.

2. Which industries benefit the most from using R&D Therm’s distillation columns?

Industries such as chemical processing, petroleum refining, pharmaceuticals, food and beverage, biofuels, and gas processing rely on R&D Therm’s distillation columns for precise separation and high-quality production.

3. How does R&D Therm ensure the safety and compliance of its distillation columns?

All distillation columns are manufactured under strict ASME Section VIII standards, carry the ASME U Stamp certification, and are built by certified welders using high-grade materials to meet global safety and reliability requirements.

4. Can R&D Therm customize distillation columns for unique production needs?

Yes, R&D Therm offers fully customizable distillation column solutions, including design specifications, material selection, and capacity, tailored to meet the exact requirements of each client’s process.

5. What materials are available for manufacturing R&D Therm’s distillation columns?

R&D Therm manufactures columns using premium materials such as Stainless Steel, Carbon Steel, and High Alloy Steels like Titanium, Hastelloy, and Sanicro 28, ensuring durability and compatibility with various chemical processes.

Please feel free to contact us.

C14/2, NICE Industrial Area, MIDC Satpur, Nashik, 422007, Maharashtra, India

C-50, MIDC Area, Malegaon, Sinnar, Nashik 422103.

Contact NowR&D Therm is a leading global manufacturer of distillation columns, designed to deliver high-efficiency separation of liqui...

At R&D Therm, we specialize in designing and manufacturing shell and tube heat exchangers, the most widely...

R&D Therm is a leading manufacturer of high-quality coded and non-coded pressure vessels, proudly carrying the ASME U stamp. Our pressure ve...

An air receiver is a critical component designed to store high-pressure air from compressors, minimizing pressure fluctuations ...

Storage tanks are vital vessels designed to store liquids or mediums for short or long-term use, operating under minimal atmospheric pressure. T...

A deaerator is a critical vessel designed to remove dissolved gases, such as oxygen and carbon dioxide, from boiler feed water....

Agitated reactors are critical equipment in various industrial processes, designed to efficiently mix, heat, or cool materials ...