Design Optimization

Engineered chemical process equipment tailored to deliver precise, efficient solutions for your production needs.

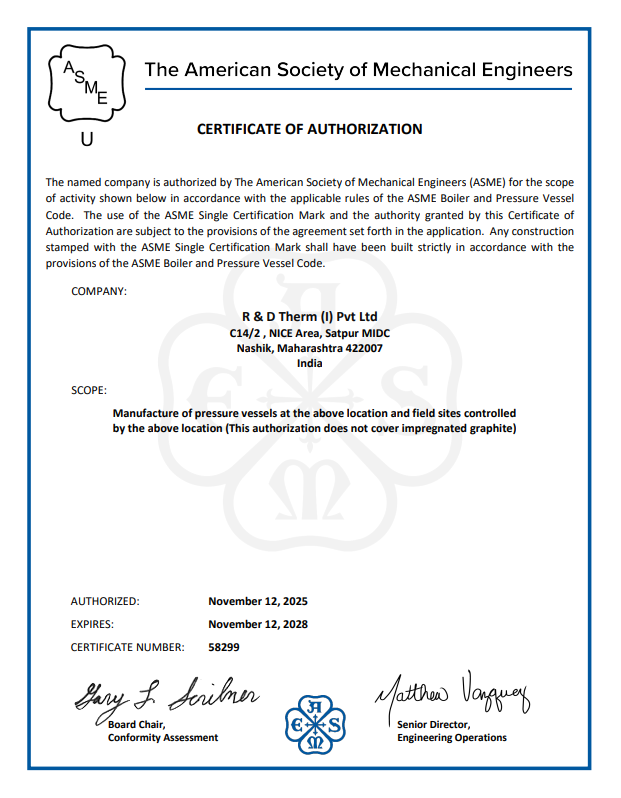

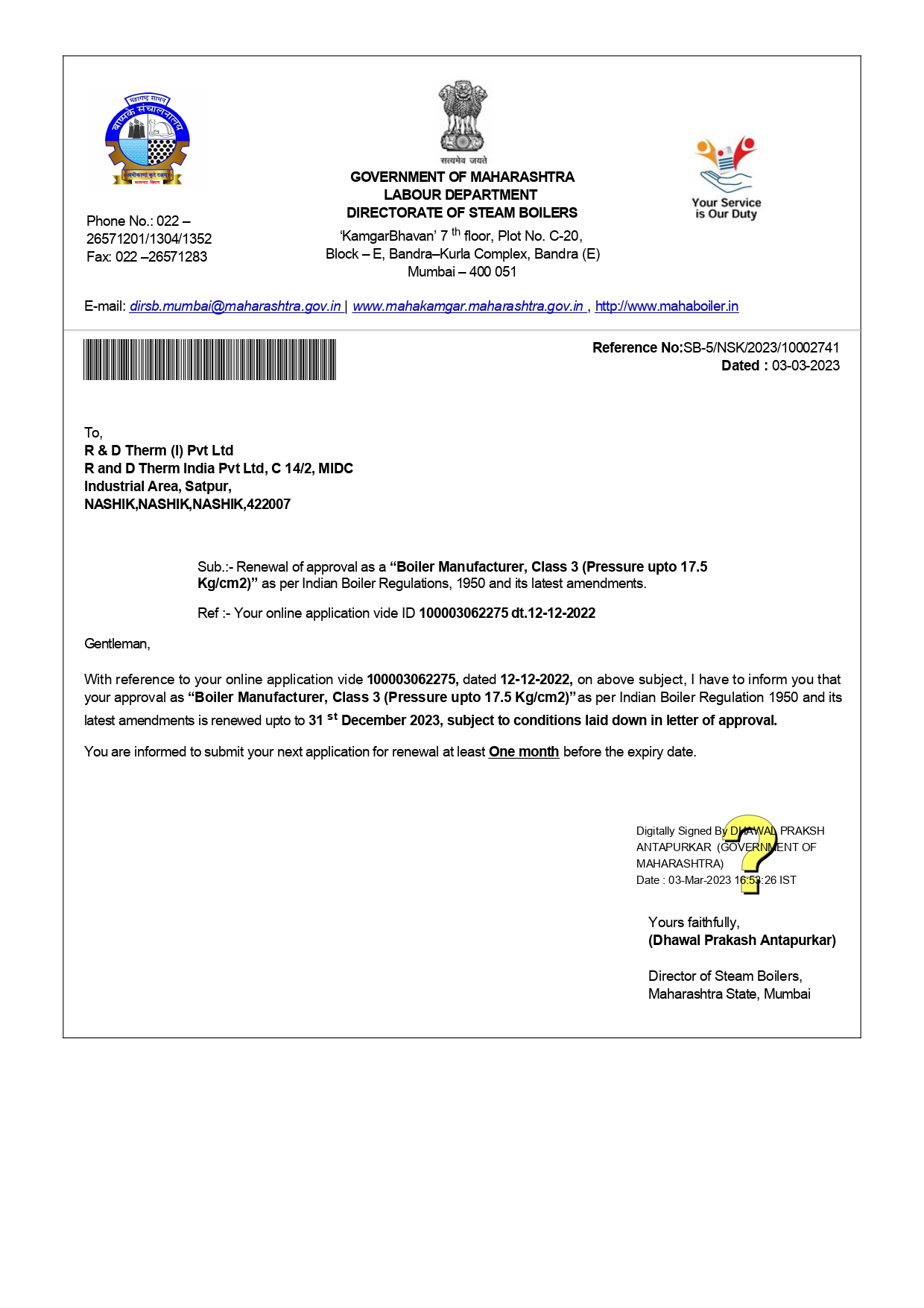

Founded in 1995, R&D Therm India Pvt. Ltd. is a leading process equipment fabricator in India with an ASME U Stamp and IBR-certified manufacturing facility based in Nashik, Maharashtra, India. With over three decades of expertise, we specialize in delivering high-quality chemical process equipment, including heat exchanger design service in India, tailored to global standards.

Our product range includes Distillation Columns for precise separation, Heat Exchangers designed for efficient thermal transfer through our expert heat exchanger design service in India, Pressure Vessels and Reactors for reliable performance, as well as Deaerators, Air Receivers, and Chimneys for diverse industrial applications.

Read More500+

Total Clients

1000+

Total Projects

5000+

Total Equipment Manufactured

30

Total Years in Business

At R&D Therm India Pvt. Ltd., our values drive excellence in delivering chemical process equipment like distillation columns, heat exchangers, and

pressure vessels. Certified by ASME U Stamp and IBR, we uphold industry-leading standards.

Engineered chemical process equipment tailored to deliver precise, efficient solutions for your production needs.

Adhering to ASME and IBR standards to ensure integrity, safety, and quality in every design.

Assuring on-time delivery to meet your project milestones and accelerate execution.

Achieving First-Time-Right (FTR) execution to elevate quality standards for pressure vessels and more.

Enhancing reliability and performance of your chemical process equipment through ongoing innovation.